How to operate a driving floor scrubber correctly

A high-quality floor scrubber can not only greatly improve work efficiency and reduce the cost investment of enterprises, but also ensure the personal safety of machine operators. Therefore, quality management is always a warning bell for ZSmart. Purchasing a driving floor scrubber is not a simple task for every company, and the price of driving floor scrubbers is not cheap, which is a significant expense for small and medium-sized enterprises. Adopting the correct usage method is helpful for the service life of the machine, and professional daily maintenance of the machine is also necessary.

After work, remove the carpet brush or floor brush and clean it to avoid deformation of the bristles caused by long-term pressure on the machine;

2. Wipe the power cord clean with a dry cloth, wrap it up and hang it on the machine;

3. Wipe the body and board (outer and bottom) clean with a dry cloth;

4. After use, drain the detergent from the water tank, add half a tank of clean water to the tank, continue draining, thoroughly clean the detergent crystals in the tank valve, otherwise it will affect the water outlet or cause water leakage;

5. The machine should be placed in a dry and ventilated place to avoid damp environments that may affect the motor and shorten its service life;

6. Empty and clean the sewage tank. During operation, the machine absorbs water mixtures containing sludge, which can easily accumulate in the water tank and emit unpleasant odors. Therefore, it is necessary to clean the water tank with flowing water;

7. Empty the water tank, especially when cleaning daily, otherwise stagnant water can become a source of bacteria.

Cleaning the water absorbing filter sometimes produces some sediment, which weakens the drying effect. Please clean the filter with tap water;

9. Clean the suction pipe connected to the suction and discharge system, as even local obstacles can weaken the water absorption effect;

10. Regularly check the water absorption filter. Sometimes the filter may be blocked by water impurities, affecting the outflow of water during the ground cleaning process;

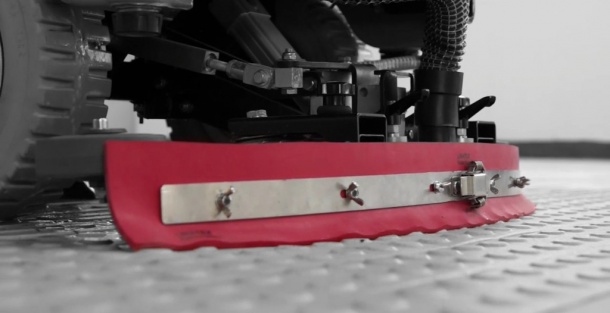

11. Check if the water absorbing steak is clean.

Check the wear of the automatic floor scrubber brush and suction scraper once a week. If the ground is extremely ground, the strong pressure on the ground can damage these components or accelerate their wear. In general, the brush disk can be replaced after 50 hours of use. On the contrary, after 30 hours of use, the absorbent tape should be replaced or flipped up and down (when all four sides of the tape are still usable).

Leave a Message